Robotiq Automation Talks

How Griffith Foods, a Global Leader in Food Manufacturing, Transformed Palletizing with Robotiq

ON DEMAND

How a Food Leader Transformed Palletizing

Join our exclusive webinar with Griffith Foods, a global leader in food ingredients, and discover how they transformed their end-of-line operations with a Robotiq Lean Palletizer .

Through this real-life case study, you’ll hear directly from the people behind the project and gain practical insights into how to plan, implement, and optimize palletizing automation in your own factory.

Key learnings you will get:

✅ A real case study from a global manufacturer — challenges, decisions, and results

✅ Where to start if you’re inspired to transform your palletizing cell

✅ Tips and pitfalls to avoid for a successful automation project

✅ The latest innovations shaping the future of cobot palletizing

Don’t miss this opportunity to learn from real experience and proven success.

WATCH THE REPLAY

OUR EXPERT SPEAKER

ELISABETH STE-MARIE

DEMAND GENERATION MANAGER

Automate or stagnate, manual palletizing is no longer viable

People

- Turn your labor scarcity into opportunity

- Provide a safer workplace, cut insurance costs

- Empower your workforce: From repetitive tasks to value-driven roles

Productivity

- Increase your throughput.

- Reduce your costs and cut downtimes

- Enhance quality by eliminating manual errors and achieving consistent output.

Adaptability

- Stay agile to respond to your changing production needs

- Be equipped to scale up with standard technology.

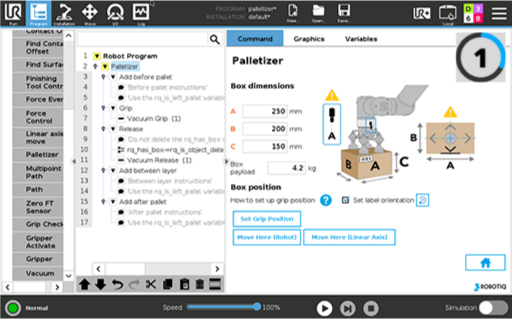

Step 1 - Box dimensions, weight and orientation