Robotiq Automation Talks - Palletizing

Exclusive Keynote by Robotiq CEO Sam Bouchard & Silas Robertson from AIT + Deanan Popcorn Success Story 🍿📦

December 5th - 10 AM PST - Register below

Curious how cobot palletizing can optimize your operations?

Join us for this 30-min webinar to uncover practical insights from over 600+ global deployments and see how Deanan Popcorn, a family-owned business, scales up with the Robotiq Palletizing Solution.

What’s Inside:

-

15-Min Exclusive Keynote by Samuel Bouchard, Robotiq CEO, & Silas Robertson from AIT

- How cobot palletizing transforms food & snack production

- End-of-line automation strategies for rapid ROI

-

Deanan Popcorn Success Story 🍿🏆

-

Project challenges & insights: overcoming tight spaces, food-grade standards

- PE20 palletizer: Why it was chosen and how to evaluate your own project

- Project costs & ROI

-

Don't miss actionable trends, live Q&A, and an exclusive look at the impact of cobot palletizing!

Can’t make it? Register to receive the recording.

Register here - December 5th

Automate or stagnate, manual palletizing is no longer viable

People

- Turn your labor scarcity into opportunity

- Provide a safer workplace, cut insurance costs

- Empower your workforce: From repetitive tasks to value-driven roles

Productivity

- Increase your throughput.

- Reduce your costs and cut downtimes

- Enhance quality by eliminating manual errors and achieving consistent output.

Adaptability

- Stay agile to respond to your changing production needs

- Be equipped to scale up with standard technology.

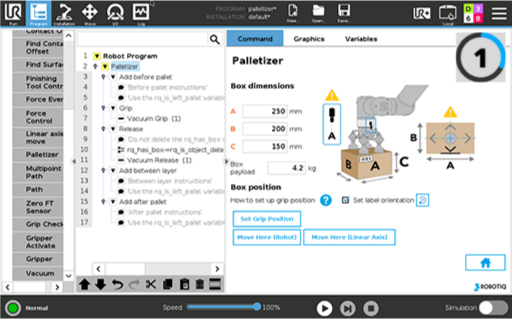

Step 1 - Box dimensions, weight and orientation

OUR SPEAKERS

Samuel Bouchard

CEO at Robotiq

Silas Robertson, SVP Sales & Marketing at AIT

Josh Davis

Senior CSM at Robotiq

" It doesn't have the big cage around it, and the footprint is so small, like it's half a pallet, and it's movable. Those two things sold me right away. On top of that, it had a third of the budget that all the other robot companies had proposed. "

Tref Hodge

Chief Operations Officer, Deanan Gourmet Popcorn