Robotiq Automation Talks

How Glenhaven Optimized Palletizing for Oven-Ready Meals: The Complete Installation

On-demand

Discover how this frozen chicken manufacturer overcame palletizing bottleneck with automation

Glenhaven faced a growing challenge: manual palletizing was becoming a bottleneck. As demand increased, so did the strain on their workforce—leading to inefficiencies, ergonomic risks, and hiring difficulties.

In this webinar, we’ll take you through their automation journey—from planning and design to installation and training—so you can see firsthand what it takes to transition from manual to robotic palletizing.

What you’ll learn:

✅ How to assess your current process and plan a seamless automation rollout

✅ Why Factory Acceptance Testing (FAT) and a standard solution minimize risk and speed up deployment

✅ How Glenhaven went from setup to full production in just 3-4 days

🚀 Discover how automation can help you scale—save your spot today!

Watch the replay

Automate or stagnate, manual palletizing is no longer viable

People

- Turn your labor scarcity into opportunity

- Provide a safer workplace, cut insurance costs

- Empower your workforce: From repetitive tasks to value-driven roles

Productivity

- Increase your throughput.

- Reduce your costs and cut downtimes

- Enhance quality by eliminating manual errors and achieving consistent output.

Adaptability

- Stay agile to respond to your changing production needs

- Be equipped to scale up with standard technology.

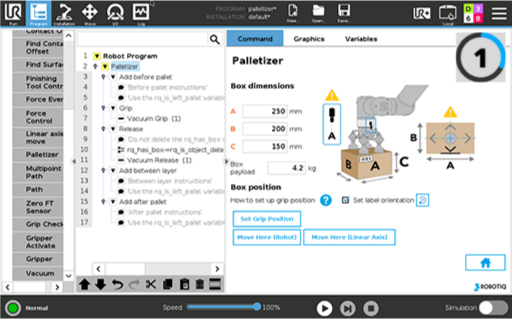

Step 1 - Box dimensions, weight and orientation