See Lean Palletizing in action at Martin Ray Winery | Feb 19th, 2026 | 1:00 -4:00 PM

A live, on-site look at how a wine producer uses cobot palletizing to handle real-world cartons, reduce manual labor, and scale throughput.

Key Event Details

📍 Where? Martin Ray Winery, 2191 Laguna Rd, Santa Rosa, CA

📆 When? February 19 | 1:00 - 4:00 PM

Event Agenda

1:00 – 1:15 | Arrival & Welcome

1:15 – 2:00 | From Manual to Lean Palletizing at Martin Ray Winery

-

Operational challenges before automation, decision process and timeline

-

Key outcomes and lessons learned

2:00 – 2:45 | Live Palletizing in Production

-

See the palletizing unit running on the actual production line

-

Walk-through of footprint, safety, changeovers, and operator interaction

2:45 – 4:00 | Wine, Networking & Peer Discussions

-

Informal conversations with Robotiq Experts & Martin Ray team

-

Open discussion around real-world palletizing experiences

👥 Who should attend?

Food & Bev manufacturers: plant managers, operations leaders, engineers, and production teams. Share with your colleagues & friends in the industry!

REGISTER TO ATTEND

Why attend this site visit

See palletizing in the real world

This isn’t a showroom or a trade show demo. You’ll see a Lean Palletizing system running in a live winery environment, handling real cartons, real variability, and real production constraints.

What you’ll take away:

-

How Martin Ray integrated cobot palletizing without disrupting operations

-

How the system handles soft, inconsistent, real-world boxes

-

What deployment actually looks like — timeline, footprint, and changeover

-

Where palletizing delivers the fastest ROI in F&B facilities

This event is ideal if you:

-

Palletize manually or with aging equipment

-

Handle soft, inconsistent, or mixed-SKU cartons

-

Are short on labor or looking to improve ergonomics

-

Want a practical, low-risk automation path

Martin Ray's Story

Martin Ray Winery, a family-owned winery in Northern California, bottles and packages a diverse portfolio of wines in printed cardboard cases. Facing labor constraints and rising costs, the winery automated palletizing with a Robotiq PE20, improving operational efficiency while targeting a 1–2 year payback.

Automate or stagnate, manual palletizing is no longer viable

People

- Turn your labor scarcity into opportunity

- Provide a safer workplace, cut insurance costs

- Empower your workforce: From repetitive tasks to value-driven roles

Productivity

- Increase your throughput.

- Reduce your costs and cut downtimes

- Enhance quality by eliminating manual errors and achieving consistent output.

Adaptability

- Stay agile to respond to your changing production needs

- Be equipped to scale up with standard technology.

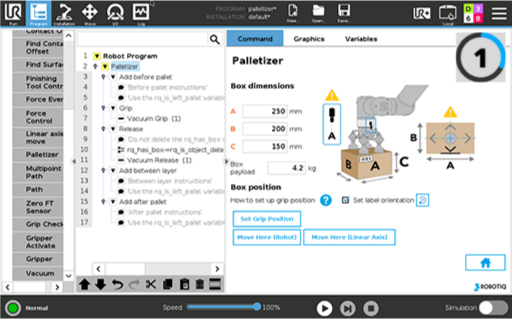

Step 1 - Box dimensions, weight and orientation

Automate Your Palletizing with Robotiq

EMPOWER PEOPLE

- Turn your labor scarcity into opportunity.

- Provide a safer and injury-free workplace.

- Empower your workforce: From repetitive tasks to value-driven roles

BOOST PRODUCTIVITY

- Increase your productivity and profits.

- Reduce your costs and downtimes.

- Enhance quality with consistent output and reduce manual errors.

ENHANCE ADAPTABILITY

- Stay agile, adapting the system to your changing needs.

- Be equipped to scale up with standard technology.

850+ factories choose Robotiq for their palletizing needs.

Read the full story

Read the full story

Read the full story

Read the full story

Read the full story

Compare the lineup

Compare Robotiq Palletizing Solution models to determine the best fit for your needs. Consider specifications such as pricing, return on investment, footprint, payload capacity, stacking height, and more. Access the comparison sheet to make an informed decision that aligns with your production-line requirements.

RELIABLE OPERATION

Robotiq palletizers are designed to be user-friendly, requiring no robotic expertise. Once installed, your staff can quickly and autonomously make modifications to the programs and accommodate production changes. You do not rely on robotic integrators for system adaptations. With the industry's largest network of certified distribution partners, we provide local expertise.

We support you throughout the deployment process and beyond.