Robotiq Automation Talks

“Panovo's leap forward: 5 Robotiq Palletizing Solutions tackling 3-meter (9-foot) stacks in frozen & ambient zones”

On-Demand

Want to fix manual palletizing? Learn how this bakery did it across 5 lines

Panovo, part of Grupo Proan, one of Mexico’s leading bakeries—eliminated 3-meter (9-foot) manual pallet stacking and improved operator well-being across five production lines.

Join us for a behind-the-scenes look at how Panovo deployed five Robotiq Palletizing Solutions to streamline end-of-line operations in both frozen and ambient environments. Discover how they:

👉Reduced ergonomic risks and labor turnover

👉Automated palletizing up to 2.75 meters in height

👉Fit compact, user-friendly cells into existing plant layouts

👉Enabled flexible handling of different product formats

👉Set clear ROI targets for payback within 3 years

This is a must-attend for food and bakery manufacturers facing space constraints, labor shortages, or shift coverage challenges.

🔹 Register to watch on-demand and explore what scalable, collaborative palletizing looks like in action.

Watch on-demand webinar now:

Mike Welch

Regional Sales Manager, Robotiq

Automate or stagnate, manual palletizing is no longer viable

People

- Turn your labor scarcity into opportunity

- Provide a safer workplace, cut insurance costs

- Empower your workforce: From repetitive tasks to value-driven roles

Productivity

- Increase your throughput.

- Reduce your costs and cut downtimes

- Enhance quality by eliminating manual errors and achieving consistent output.

Adaptability

- Stay agile to respond to your changing production needs

- Be equipped to scale up with standard technology.

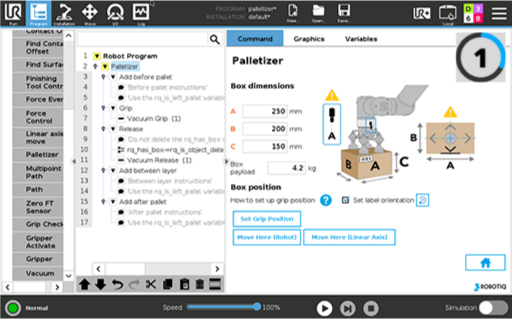

Step 1 - Box dimensions, weight and orientation