Robotiq Automation Talks

The Future of Beverage Palletizing: Raumland's Successful Cobot Journey

On-demand

The Future of Beverage Palletizing: Raumland's Successful Cobot Journey - On-demand

Discover how this wine manufacturer overcame manual palletizing challenges with a 3-day deployment and 14-month ROI cobot solution

Raumland GmbH processes over five million bottles and 2,500 different wines every year, creating a huge diversity in its bottling operations.

In a single 8-hour shift, employees had to handle up to 40 tonnes of packaging, which was inefficient and physically demanding.

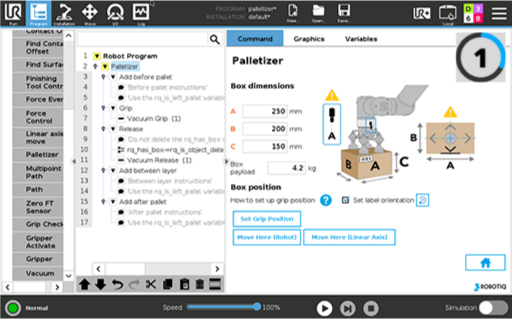

To tackle this problem, Raumland GmbH successfully used Robotiq's PE20 Palletizing Solution with the UR20 cobot from Universal Robots.

During this 30-minute webinar, we discuss the steps from the design phase to integration and operation including cost analysis, ROI and how to begin your project.

OUR SPEAKERS

Will Gilchrist

Regional Sales Manager, North Europe

Elisabeth Ste-Marie

Field Marketing Manager, Robotiq

Watch the replay

Automate or stagnate, manual palletizing is no longer viable

People

- Turn your labor scarcity into opportunity

- Provide a safer workplace, cut insurance costs

- Empower your workforce: From repetitive tasks to value-driven roles

Productivity

- Increase your throughput.

- Reduce your costs and cut downtimes

- Enhance quality by eliminating manual errors and achieving consistent output.

Adaptability

- Stay agile to respond to your changing production needs

- Be equipped to scale up with standard technology.

Step 1 - Box dimensions, weight and orientation

The cobot perfectly reflects what we need. It is a flexible machine, compact, quick to set up, and, ultimately, affordable. We were able to automate a task that was extremely tedious. No one complains about back pain anymore. At least not from palletizing.

Sebastian Raumland

Managing Director, Raumland GmbH